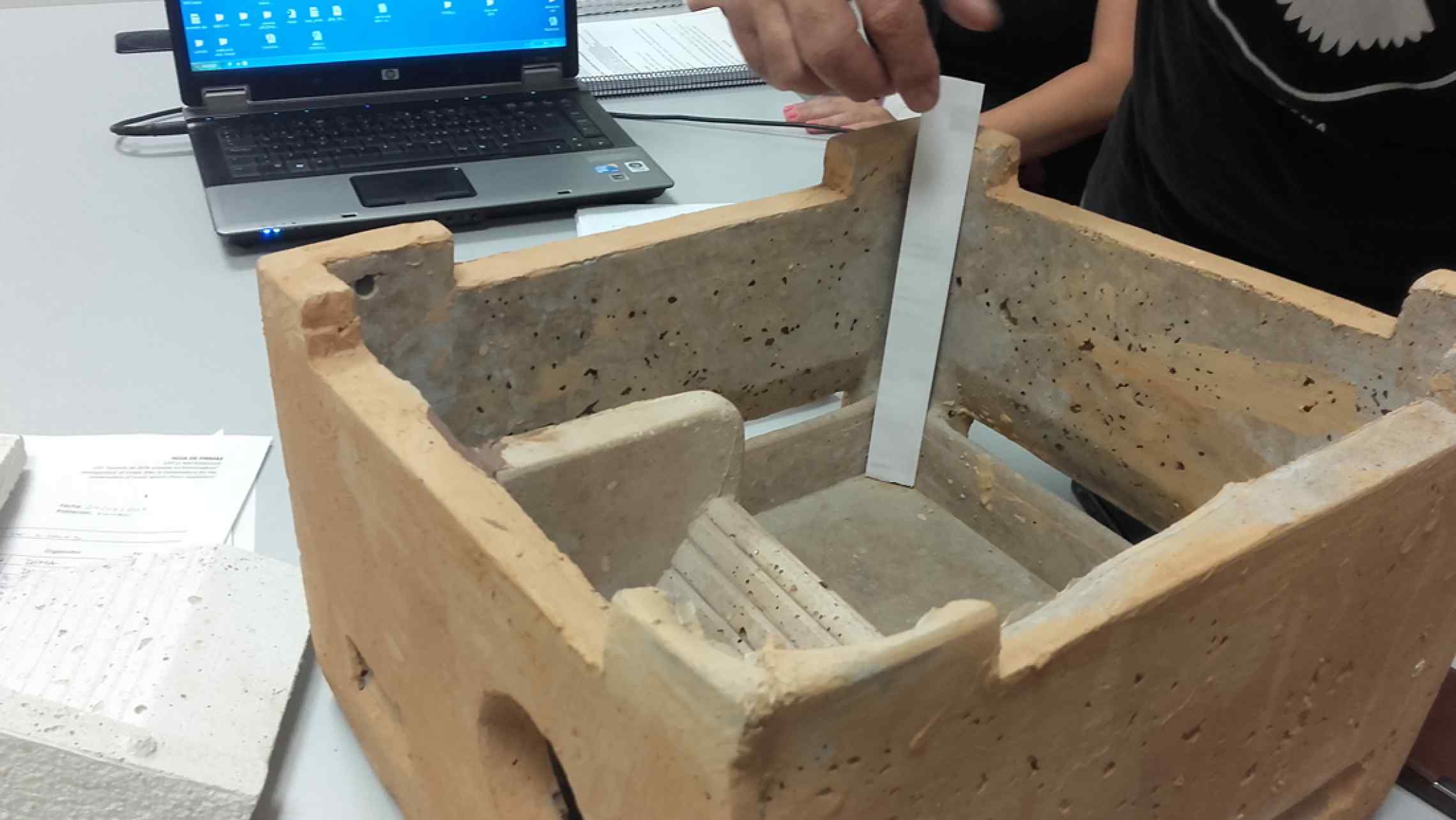

On 24th July the team involved in action A6 (“Industrial manufacture of mortar-cork nest boxes”) of the LIFE-ZEPAURBAN project met to assess the performance of the new nest boxes in the various tests carried out. INTROMAC expounded the temperature results of those installed on the roof of the Church of Nuestra Señora de la Purificación (the ZEPA for lesser kestrel colonies in Almendralejo) and those of the tests carried out at their facilities on temperature, thermal shock, and impact. For its part DEMA assessed the performance of the nest boxes concerning their acceptance by the species and the ethological suitability of the prototype, for which purpose it revealed the results obtained for the five boxes installed on the aforementioned roof. Finally Prefabricados Extremadura 2002, which was responsible for the manufacture of the new nest boxes, analysed their demoulding and industrial production.

Despite the fact that the nest boxes were installed when many pairs appeared to have already selected their nesting sites, their acceptance by the species was very positive with the occupation of 3 of the 5 installed. Moreover, the efficiency of some of the measures implemented in the new prototype was confirmed, such as the slots for ventilation and the evacuation of excrement.

As for the temperature, this was improved compared with other nest boxes currently on the market: the sensors installed inside the new prototypes gave readings of approximately two degrees lower than ambient temperature, while the same sensors installed in those already on the market recorded higher figures than the surroundings. Moreover, when the outside temperature dropped that of the interior of the nest box developed for the LIFE-ZEPAURBAN project did so almost at the same time, while in the nest boxes already on the market it took longer to do so. The ventilation of the new nest boxes is highly efficient, which together with the improved insulation of the material avoids the oven effect; no significant differences were detected between the various colours tested (white, grey, and ochre).

The weight was reduced at least 3 kg compared with the nest boxes already on the market; despite this the breaking behaviour on impact for the new boxes has been improved owing to the inclusion of cork. Moreover, the available nesting space has been increased. As far as industrial manufacture is concerned, the moulds that have been developed are satisfactory and their performance is expected to allow the demand to be met.

Although in 2018 we will continue to install nest boxes in the urban ZEPAs of Extremadura so as to become more familiar with their performance from all the points of view analysed, the team was very satisfied with the results obtained. Everything seems to indicate that we are on the road to achieving the objectives of this action: nest boxes ethologically adapted to the requirements of the species and that are lighter, more economical, and more resistant. Moreover, the temperature improvement for all colours tested has increased expectations of integration with the buildings on which they are installed, which is particularly important when these are of heritage value.